DairyProQ

Designed specifically for large-scale dairy farms, the GEA DairyProQ robotic milking carousel offers outstanding advantages in operational efficiency and animal welfare.

Key Advantages:

- Effortless and User-Friendly Operation

- Precise and Consistent Milking Connection

- Proactive Cow Health Monitoring

Transform your milk production with GEA DairyProQ and experience the future of milking today.

Efficient Bulk Milking Starts Here!

Discover the future of dairy farming with DairyProQ, GEA’s cutting-edge rotary milking system designed for farms of all sizes. From operations with just 600 cows to the world’s largest systems processing over 5,000 cows, our technology sets the standard for efficiency and productivity. With DairyProQ, you can scale seamlessly and push the boundaries of what’s possible in dairy farming. Trust us to take your milk production to unprecedented levels!

Highest productivity and quality for large-scale farms

Boost your dairy farm’s efficiency with the DairyProQ milking carousel. This high-tech system delivers high productivity with minimal staffing, allowing you to milk 120 to 400 cows per hour with consistent quality and flexible scheduling. In a trusted partnership with GEA, DairyProQ offers continuous service, innovative online monitoring, and minimal downtime. Benefit from proven technology and expert support, with manual backup for emergencies. Invest in DairyProQ for a productive, safe, and future-proof dairy operation.

Highest Milk Quality

Ensure high-quality milk production with the DairyProQ milking carousel. One-on-one milking service promotes gentle milking and optimal udder health. Features like individual milking for each udder and 3D cameras ensure superior milk quality.

Productive Working Environment

Transform your dairy farm with the DairyProQ milking carousel. This system reduces manual work, lowers personnel requirements, and makes animal management more efficient with streamlined, flexible scheduling.

Always Productivity

Increase your dairy farm’s productivity with DairyProQ. Able to milk 120-400 cows per hour, this system requires minimal personnel and delivers consistent quality. Its modular design ensures efficient, uninterrupted operation and a rapid return on investment for large herds.

Trusted Partnership

Grow with DairyProQ and GEA. Enjoy uninterrupted service, online monitoring, and minimal downtime. Our technology and support ensure reliable operation with emergency backup. Choose DairyProQ for a secure dairy partnership.

Our Automatic Milking Systems: Proven Features for Your Farm’s Success!

When you choose a GEA automatic milking system, you benefit from cutting-edge technology designed to increase productivity, improve comfort, and enhance animal welfare. Transform your dairy operations today with advanced automatic milking solutions from GEA.

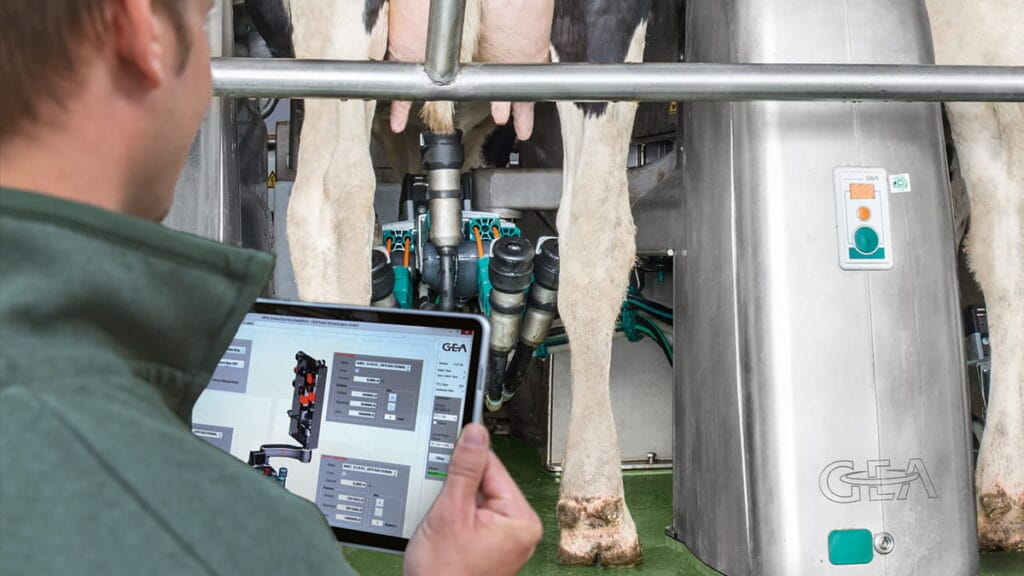

AFTER THE COW IS IDENTIFIED, THE SIZE OF THE MILKING UNIT IS ADJUSTED AUTOMATICALLY TO THE ANIMAL.

When Cowscout detects cows due for milking, the adjustable feed trough adapts the size of the milking unit to the cow’s size. This ensures the udder remains in the same position at all times, allowing the milking arm to be positioned quickly. This not only saves time but also energy. You can also divide the concentrate into individual rations.

QUALITY CONTROL FOR

EACH NIPPLE SEPARATELY

The DairyMilk M6850 is the world’s first somatic cell counting system that focuses on each teat individually throughout the entire milking process. This early detection system alerts you at the first sign, helping you minimize treatment time, ensure recovery, and ensure the continued productivity of your healthy herd.

DISPOSABLE NIPPLE TIP

In all our automatic milking systems (AMS), the milking arm is positioned directly under the cow’s udder in just one movement. As a pioneer in 3D camera teat detection, we offer extremely fast cluster installation with minimal movement.

In the DairyRobot R9500 model, all motors stop when the milking cups are attached to the teats. A milk rack system monitors the cow’s movements throughout the milking session. If a milking cluster is kicked off, short milk hoses prevent it from falling to the ground and becoming contaminated, and the cluster can be immediately reattached.

EXCLUSIVELY FROM GEA – EXPERIENCE THE DIFFERENCE WITH IN-LINER-EVERYTHING TECHNOLOGY, WHERE ALL OPERATIONS ARE PERFORMED WITH A SINGLE TOOL.

From stimulation to cleaning—all in one process. The In-Liner Everything process revolutionizes the entire milking procedure by seamlessly integrating every step: stimulation, teat cleaning, milking, and post-milking. And it all happens in one seamless cycle—with a single tool. This innovative process was developed exclusively by GEA and is available exclusively with our automatic milking systems. It optimizes animal handling, saves valuable time, and increases consistency and hygiene with every milking session. Discover the future of automated dairy farming with GEA’s In-Liner Everything technology.

AFTER THE COW IS IDENTIFIED, THE SIZE OF THE MILKING UNIT IS ADJUSTED AUTOMATICALLY TO THE ANIMAL.

When Cowscout detects cows due for milking, the adjustable feed trough adapts the size of the milking unit to the cow’s size. This ensures the udder remains in the same position at all times, allowing the milking arm to be positioned quickly. This not only saves time but also energy. You can also divide the concentrate into individual rations.

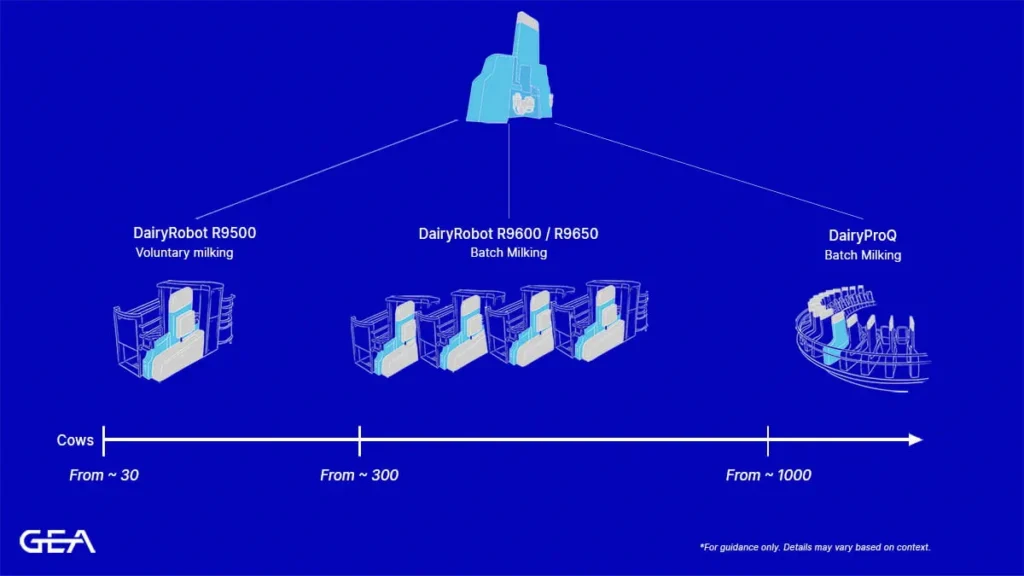

The best for your dairy farm with our unique platform strategy!

Our Automatic Milking Solutions

Regardless of your herd size, barn layout, or personal preferences, our unique platform strategy offers you all the innovative benefits of our automatic milking systems in a variety of setups. Whether it’s voluntary milking, sequential group milking, or carousel milking, we’ll find the individual solution for you and your farm!